Downloads

Keywords:

Optimizing Laser Heat Treatment to Enhance Phase Stability and Hardness in NiTi Alloys for Implants

Authors

Abstract

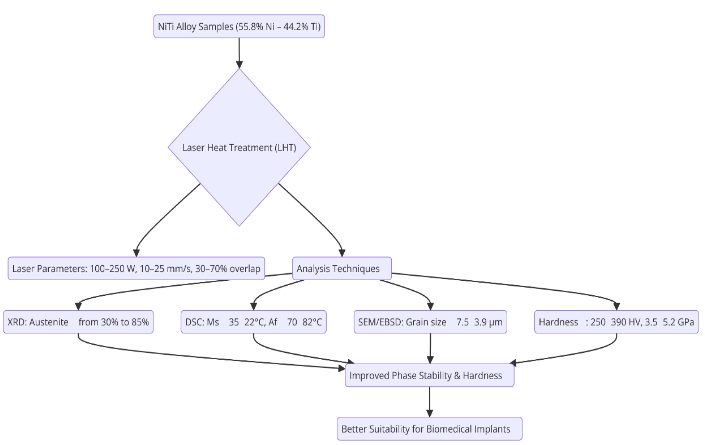

This study investigates the effects of Laser Heat Treatment (LHT) on the phase stability and hardness of NiTi shape memory alloys (SMAs), aiming to enhance their suitability for biomedical implant applications. Traditional heat treatment methods like annealing and aging often suffer from drawbacks such as grain coarsening and uncontrolled phase transformations. In contrast, LHT offers a localized and rapid thermal process that promotes microstructural refinement, improved mechanical properties, and enhanced phase stability.

NiTi alloy samples (55.8 wt.% Ni – 44.2 wt.% Ti) were treated using a 1070 nm fiber laser, with laser power ranging from 100 W to 250 W, scan speeds from 10 mm/s to 25 mm/s, and overlap ratios from 30% to 70%. Phase transformation behavior was characterized using X-ray Diffraction (XRD) and Differential Scanning Calorimetry (DSC), while microstructural changes were examined via Scanning Electron Microscopy (SEM) and Electron Backscatter Diffraction (EBSD). Mechanical performance was assessed through Vickers microhardness and nanoindentation testing. Response Surface Methodology (RSM) was used to identify optimal LHT parameters.

The results demonstrated a substantial increase in austenite phase fraction, from 30% (untreated) to 85% (LHT-treated), and a significant decrease in martensite start temperature from 35°C to 22°C, along with a rise in austenite finish temperature from 70°C to 82°C. Grain size was reduced from 7.5 µm to 3.9 µm under optimal LHT conditions, and hardness increased from 250 HV to 390 HV and from 3.5 GPa to 5.2 GPa in nanoindentation tests.

This study confirms that LHT is an effective surface treatment technique for improving phase stability, microstructural uniformity, and mechanical strength in NiTi SMAs. Optimized LHT conditions (200–250 W, 15–20 mm/s scan speed, 50–70% overlap) enhance the performance of NiTi alloys, making them more reliable for use in orthopedic and cardiovascular biomedical implants.

Article Details

Published

Issue

Section

License

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.